Drywall Calculator – Estimate Cost and Material

Calculate drywall or Sheetrock panels, screws, joint compound, and tape needed for your project by entering your room’s dimensions. Optionally include the ceiling if you’re drywalling that as well.

Drywall Material Estimate:

| sheets: | |

| estimated cost: | $ |

Other Materials

| screws: | |

| tape: | |

| ready-mix: | |

| lightweight mix: | |

| quick setting mix: |

Project Size

On this page:

How to Calculate Drywall

Drywall, also referred to as Sheetrock or wall-board, is used to cover wall studs in modern construction. Drywall creates the solid wall surfaces you see in your home.

It’s usually finished and painted after installation. When you’re completing a renovation or construction project, you’ll likely need drywall to cover the studs or wall frame of the home.

There are a few ways to estimate the amount of drywall and materials you’ll need for the project.

The first method is to use the drywall calculator above.

Enter the size of your room, and the drywall calculator finds the square footage of the walls, estimates the amount of drywall needed to cover those surfaces, and estimates additional supplies, including screws, joint compound, and tape.

How to Estimate Drywall Without a Calculator

To estimate the amount of drywall needed for your project, you need to calculate the square footage of the walls and ceilings that you’ll be sheetrocking.

Square footage of the walls is the length in feet times the width in feet of each wall. , Thus, you can calculate square feet by multiplying the length times the width.

Do this for each wall, then add them all together to get the total square footage.

If the walls are complex and not rectangular, then it may be easiest to split the walls into smaller sections, and calculate each section individually, then add them together.

For example, to measure walls that have a vault, it will be easiest to determine the square section and vault separately.

If you have doors, windows, or other areas where you won’t be installing drywall, find the square footage of those areas and subtract it from the total square footage figure. This will make your calculation more accurate and reduce excess materials and waste.

After you find the square footage of drywall needed, simply divide it by the square footage of the sheet size you will be using to find the number of sheets needed.

For example, if your wall surface is 1,000 square feet and you’re using 4′ x 8′ sheets, which have 32 sq ft per sheet, then the number of sheets needed is 1,000 ÷ 32, or 31.25. Round up to the nearest full sheet.

We suggest ordering about 10% additional materials to account for cuts and material waste. Having additional material can help prevent delays due to waste for offcuts and broken pieces.

How to Estimate Joint Compound and Tape

Estimating the amount of joint compound and drywall tape you need starts with finding the square footage. Different joint compound or mud products have different coverage levels, so it’s best to check the product you intend to use to verify the coverage.

If you’re using a lightweight joint compound (not premixed), then you’ll probably need 0.053 pounds of mud per square foot of drywall. If you’re using a quick-setting product, then you’ll likely need 0.073 pounds of mud per square foot. Drywall tape typically covers about 2-3 square feet of Sheetrock per foot of tape.

Likewise, when finishing the drywall, it may be given different textures. These textures may change the amount of coverage that a compound could give you.

How to Estimate Drywall Cost

To effectively estimate the cost of a drywall project, you need to calculate how many sheets you’ll be installing, the tape and joint compound required, and how many screws are necessary for the project.

Keep in mind that there are different types of drywall for different areas. For example, drywall that is mold or moisture-resistant is best for bathrooms. These can have different costs as well.

The calculator above can estimate the material costs for the project, but every drywall project needs one critical component – a skilled laborer to install and finish the project.

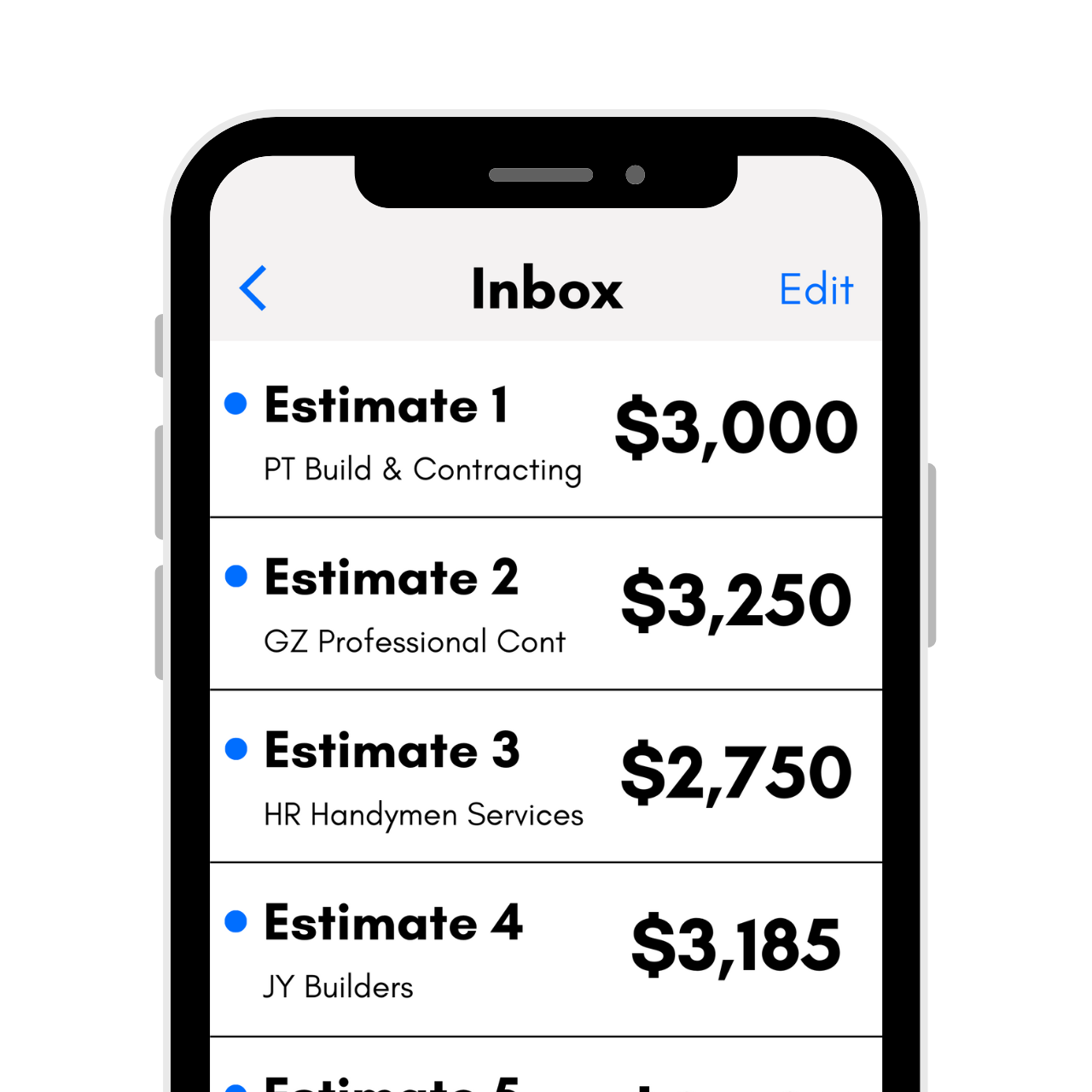

The cost of labor varies drastically based on your geographic area and the skill of the craftsmen. We suggest getting several quotes in your area to get an accurate cost estimate for the project.

You can also use our drywall cost calculator to estimate the cost of the project in your area.

Bear in mind that more complex framing, layouts, or exclusions will require manual estimation of materials, any automated estimation will have a reduced level of accuracy as the complexity of the framing or exclusions rises.

Sheetrock Panel Size Factors to Consider

- Long sheets require fewer seams and cost much less to finish, but are more difficult to install.

- Long sheets may not fit in tight spaces or through stairwells.

- Long sheets are significantly heavier to lift and transport. A 4’x8′ 1/2″ sheet of drywall weighs 54 pounds, while a 4’x12′ 1/2″ sheet weighs 82 pounds.

Don’t forget to consider transportation and delivery requirements when ordering materials. Drywall products are very heavy, and you’ll want to make sure you have the appropriate tools for moving large amounts of Sheetrock.

We recommend using a panel carry tool, which basically adds a set of handles at just the right height to make carrying large Sheetrock panels very easy.

As an Amazon Associate, we may earn commissions from qualifying purchases from Amazon. Learn more

Using tools like this can make life easier moving heavy sheets, but can also help prevent damage to the drywall sheets as well.

Frequently Asked Questions

Is drywall exactly 4x8?

If you are purchasing 4′ x 8′ sheets, then yes; they are designed to butt against one another. Drywall can be found in many different sizes, however, such as 4′ x 10′ and 4′ x 12′, as well as different thicknesses, such as 1/4″, 1/2″, and 5/8″.

What size of drywall should you use for walls?

The most common size of drywall for walls is 4′ x 8′. However, if you have taller ceilings or an unusual layout, you can purchase larger sheets as well.

How much drywall do you need for a 10x10 room?

If the room is exactly 10′ x 10′ with a 9′ ceiling, then you would need 15 sheets of 4′ x 8′ drywall to cover the walls and ceiling. Likely, this number will be lower, however, once things like doors and windows are subtracted.

Are drywall and Sheetrock the same thing?

Yes, in that Sheetrock is a brand of drywall. Much like people use brand names like Kleenex or Jacuzzi to describe a product, Sheetrock is sometimes used to describe generic drywall.